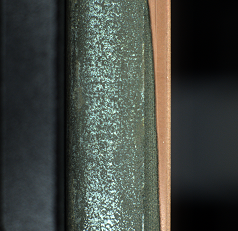

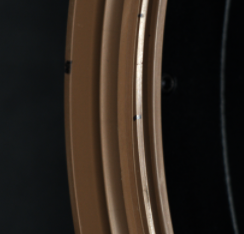

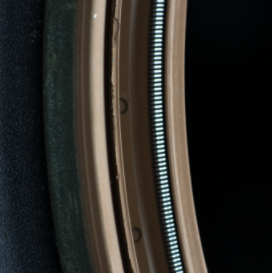

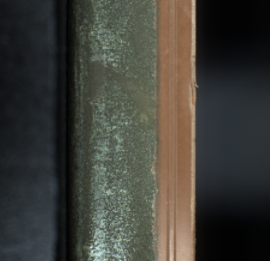

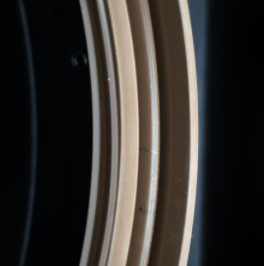

AOI Machine for Sealing Ring Appearance Defects

It adopts multi-angle multi-station imaging mode, 360 degrees without dead Angle detection, any functional surface, details can be 100% full inspection. Using high-precision industrial cameras and unique imaging methods. There are different mechanism solutions for products of different size segments to meet the beat requirements of various products. Self-developed image software, independent intellectual property rights; At the same time, it can adapt to different manufacturers and different customization requirements, and has strong compatibility. The combination of traditional algorithm and AI algorithm is used to detect defects accurately and reduce the misjudgment rate.

Machine Vision

Machine Vision Bearing

Bearing AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI MACHINE FOR Wheel Hub Bearing Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Sealing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS

AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI MACHINE FOR Wheel Hub Bearing Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Sealing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS